Blasting systems and blast cabinets

Blasting technology is the overall term for all the blasting methods applied to mechanically change the properties of surfaces using abrasive blasting agents.

In classic blasting technology, the individual grains of the blasting abrasive used represent the tool with which the surface is mechanically treated. In this process, the particles are aimed at the surface in a jet with the aid of a carrier medium – traditionally compressed air or water. The jet is both a carrier medium and a source of the kinetic energy required for blasting with which the grains are accelerated. Different blasting methods are used depending on the intended purpose and the texture which is to be achieved.

The fields of application for blasting technology extend to almost every sector of industry. The spectrum ranges from minute parts with diameters of a few millimetres to entire ships or bridge structures in which the outer walls are blasted using the open jet method.

In the field of manufacturing, blasting is one of the most important methods of mechanical surface treatment. Due to the very fast and extremely effective procedure, it is ideal for industrial production. Blasting processes used in production operate in a closed cycle without harming the environment. The blasting media and residues used can usually be disposed of without any restrictions.

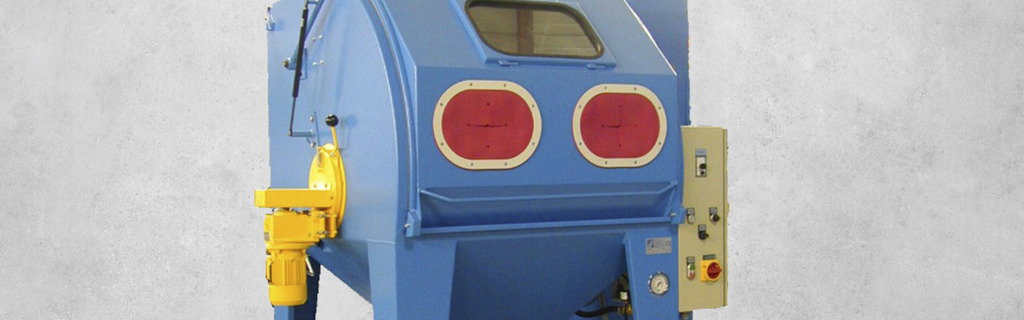

All AUER blasting systems and blast cabinets can be operated with a choice of compressed air, wet blasting or turbine blasting methods. The individual techniques essentially differ in the blasting power generated over the surface area and in the energy carrier medium.

The following blasting methods are possible:

- INJECTOR BLASTING

- GRAVITATION BLASTING

- PRESSURE TANK BLASTING

- WET BLASTING

- TURBINE BLASTING

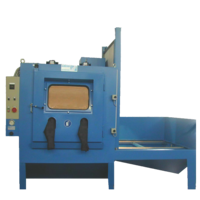

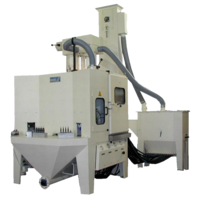

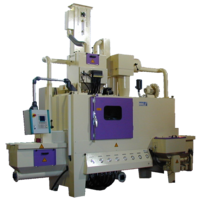

Conveyor sandblasting machine

Applications:

- Matt coating of oven panels and aluminium strips

- Roughening of sheets and brake linings

- Deburring of plastic parts

Material: Strong and robust welded assembly, blast cabinet made of 3-5 mm-thick sheet steel.

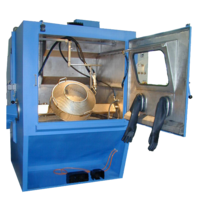

Supplied as standard with the product:

- High-power blast guns

- Conveyor belts made of rubber, steel plates or wire

- Infinitely variable belt speeds

- Hopper screw and bucket elevator for mechanical blasting agent circuit

- Cyclone separator for recirculation of blasting abrasive

- Central control cabinet with PLC and OP

| Attachment | Size |

|---|---|

| 4.05 MB |