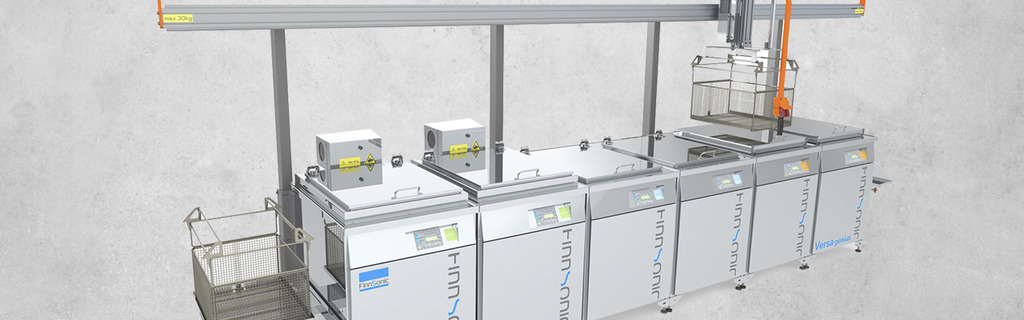

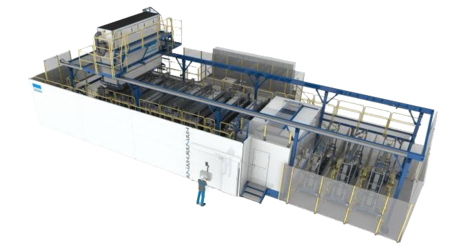

Immersion and ultrasonic cleaning systems

Immersion cleaning method

Immersion cleaning methods are preferred when the job entails cleaning parts with complex geometry, featuring blind holes and/or indentations, for example. When the workpiece is immersed in the cleaning solution, the chemical action of the cleaning agent removes any stubborn dirt. The cleaning effect is increased by turning or rotating the parts in the solution and/or by using ultrasonic systems.

Ultrasonic cleaning

Ultrasonic cleaning is based on the cavitation effect in that the bath liquid is treated with an ultrasonic generator and a synchronised vibrating system. The resulting vibrations cause minute cavities to form in the liquid and immediately collapse again. This creates strong currents and turbulence which “blast off” the dirt from the items being cleaned.

Pressure bypass cleaning

Pressure bypass cleaning is a process in which pumps draw liquid from the bath and then pump it at high pressure through a nozzle system located below the liquid level. This creates strong currents which cause turbulence to impact on the edges of the components and detach the dirt. As the liquid flows past blind holes and recesses, a suction effect is also created which sucks out the impurities contained in the holes and recesses.