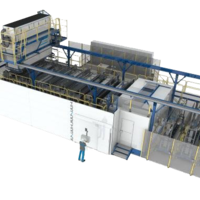

FinnSonic Optima customised ultrasonic cleaning systems (manual and fully automatic)

The FinnSonic Optima systems are flexible solutions in cases where high levels of capacity are required for component cleaning. FinnSonic Optima is used in various industries with the highest purity standards and capacity requirements.

Treatment modules

- Ultrasonic cleaning

- Jet spray cleaning

- SonicJet cleaning technology

- Rinsing

- Spray washing

- Hot air drying

- Vacuum drying

- Optional extras

- Cage agitation

- Rotating cages

Tank volume

From 150 litres to over 10 m3

Cage dimensions

- From 400 x 300 x h 300 mm or made to customer specifications

- Cages can be up to several metres in length in long versions

Maximum load

- 35 kg to over 10 tons

Ultrasonic agitation

- 1.2 kW to over 30 kW

- Frequencies of 20, 30 and 40 kHz

Liquid disposal

- Storage tanks

- Particle filters

- Oil separators

- Automatic filling and measuring units

Material handling and process automation options

- PTM easy lift, automatic cage handling for loads of up to 50 kg

- CH cage handling function with chain hoist, 50 to 1000 kg

- LP load platform for tanks with lifting and agitation functions for 40 to 1000 kg

- MBT for fully automatic treatment and process control for several cages

- 100, 200, 400 or 1000 kg

- Custom-made solutions

- With safety barrier or full enclosure

- Conveyor systems

Technical specifications: