Cleaning // of aircraft rims, wheel bearings, bolts, nuts and brake parts

The highest demands are placed on the design of the systems used in the aviation industry to clean aircraft rims, wheel bearings, bolts, nuts and brake parts. There are essentially three different procedures:

Rim cleaning is based on a combination of powerful cleaners and rotating brushes which do a thorough job of removing carbon deposits, grease and rubber residues. This process, which is far more efficient and more sparing with resources than conventional wheel cleaners, uses environmentally friendly water-based chemical cleaning solutions to achieve optimum results.

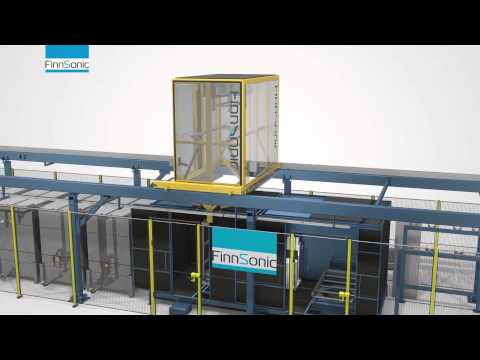

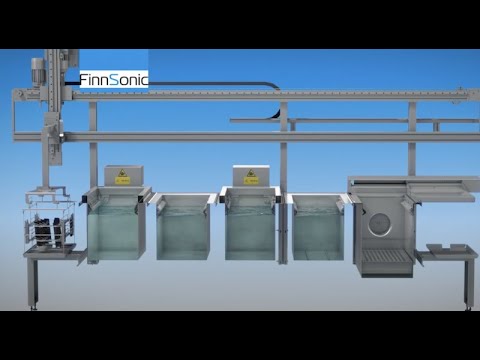

When cleaning fuselage parts, the particular challenge lies in the very different dimensions of the parts which need to be cleaned and in the intricate shapes of the parts which may require special treatment in certain circumstances. Individual components can be sprayed down with water jets before the actual cleaning proceeds by way of an ultrasonic process. The process also includes the manual cleaning of parts with a spray lance and drying with a hot air circulation system. There is a highly sophisticated control system to take care of various jobs, including the precise recording of temperatures and process data.

The wheels and rim section of the cleaning system is designed to enable the thorough cleaning of various parts, such as wheel bearings, bolts, nuts and brake components. In the final stage, the components are rinsed thoroughly to remove the cleaning agent residues.